How precast concrete scaffold blocks are enhancing health & safety for scaffolders

In a high-risk trade like scaffolding, safety comes first. Scaffolders face daily hazards that demand skill, concentration and robust systems to reduce risk and improve working conditions. One practical innovation making a real difference is the use of precast concrete scaffold blocks.

Traditionally used as ballast for temporary structures, these ready-made blocks have become a safety asset on construction sites. Here’s how precast scaffold blocks are improving health, safety and day-to-day conditions for scaffolders across the UK.

Stable, reliable bases

One of the biggest advantages is base stability.

-

Even weight distribution: Unlike improvised bases (such as timber offcuts or uneven ground), precast blocks spread loads consistently, reducing the risk of movement or settlement.

-

Less ground preparation: Minimal groundwork lowers manual effort and exposure on rough terrain.

-

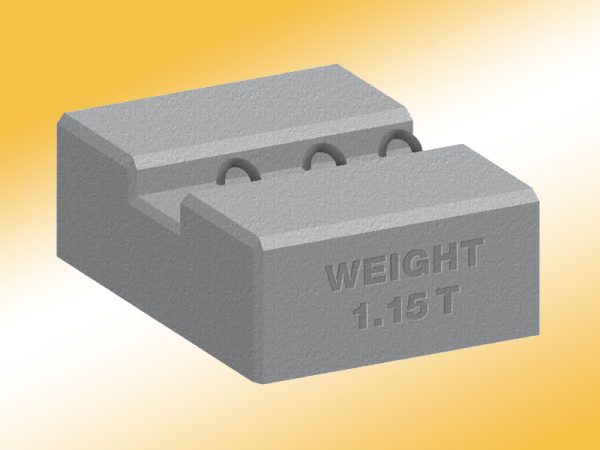

Better load bearing: Quality precast blocks are engineered for heavy loads, keeping scaffolds steady under working conditions.

By creating a secure foundation, these blocks help prevent tipping, collapse and tilting—common causes of scaffold incidents.

Lower manual-handling risk

Manual handling is a major source of injury, especially where heavy components are lifted and positioned frequently.

-

Standard sizes and lifting points: Consistent dimensions and optional cast-in lifting loops support mechanical handling.

-

Ergonomic handling: Purpose-made units are moved by plant rather than people, reducing strain and injury—particularly important for an ageing workforce.

Faster, safer set-ups

Tight deadlines can pressure teams to cut corners. Precast blocks help preserve safety without slowing progress.

-

Quicker deployment: Uniform units speed installation compared with site-built or ad hoc bases, reducing time on site and exposure to hazards.

-

Tidier work areas: Clearly defined, consistent base locations improve layout, cut trip hazards and reduce misalignment during assembly.

Built for UK weather

Outdoor work is shaped by heat, rain, ice and frost. Precast blocks are designed to cope.

-

Non-degrading surfaces: Unlike timber or soil supports, concrete stays solid and slip-resistant in wet conditions.

-

Low maintenance: Once in place, little adjustment is needed, limiting returns to hazardous zones.

-

Resistant to frost heave: Properly manufactured blocks help maintain alignment through winter.

-

No special UV protection required.

Less risk on site through off-site manufacture

Moving processes off site improves quality and reduces exposure to harmful by-products.

-

Factory control: Precast blocks are made in monitored conditions for consistent quality and fewer defects. Suppliers such as Elite Precast Concrete operate to ISO 9001, ISO 14001 and ISO 45001, giving added assurance.

-

Cleaner sites: With no on-site casting or cutting, there’s less noise, dust and silica exposure.

Supporting compliance

Using precast scaffold blocks helps duty-holders align with:

-

HSE guidance on safe scaffolding

-

The Manual Handling Operations Regulations (MHOR)

-

CDM Regulations 2015

Reducing variability and known risks makes it easier to demonstrate planning, competence and control.

Conclusion

Precast concrete scaffold blocks may look like a small detail, but for scaffolders they deliver a meaningful safety gain. They improve stability, cut manual-handling injuries, speed installation and support regulatory compliance. As the industry continues to prioritise worker welfare, practical measures like high-quality precast bases show how simple, solid solutions can make the biggest difference on the ground.

Visit the Elite Precast Concrete Ltd website for more information on How precast concrete scaffold blocks are enhancing health & safety for scaffolders